Platform Capability

Production Monitoring

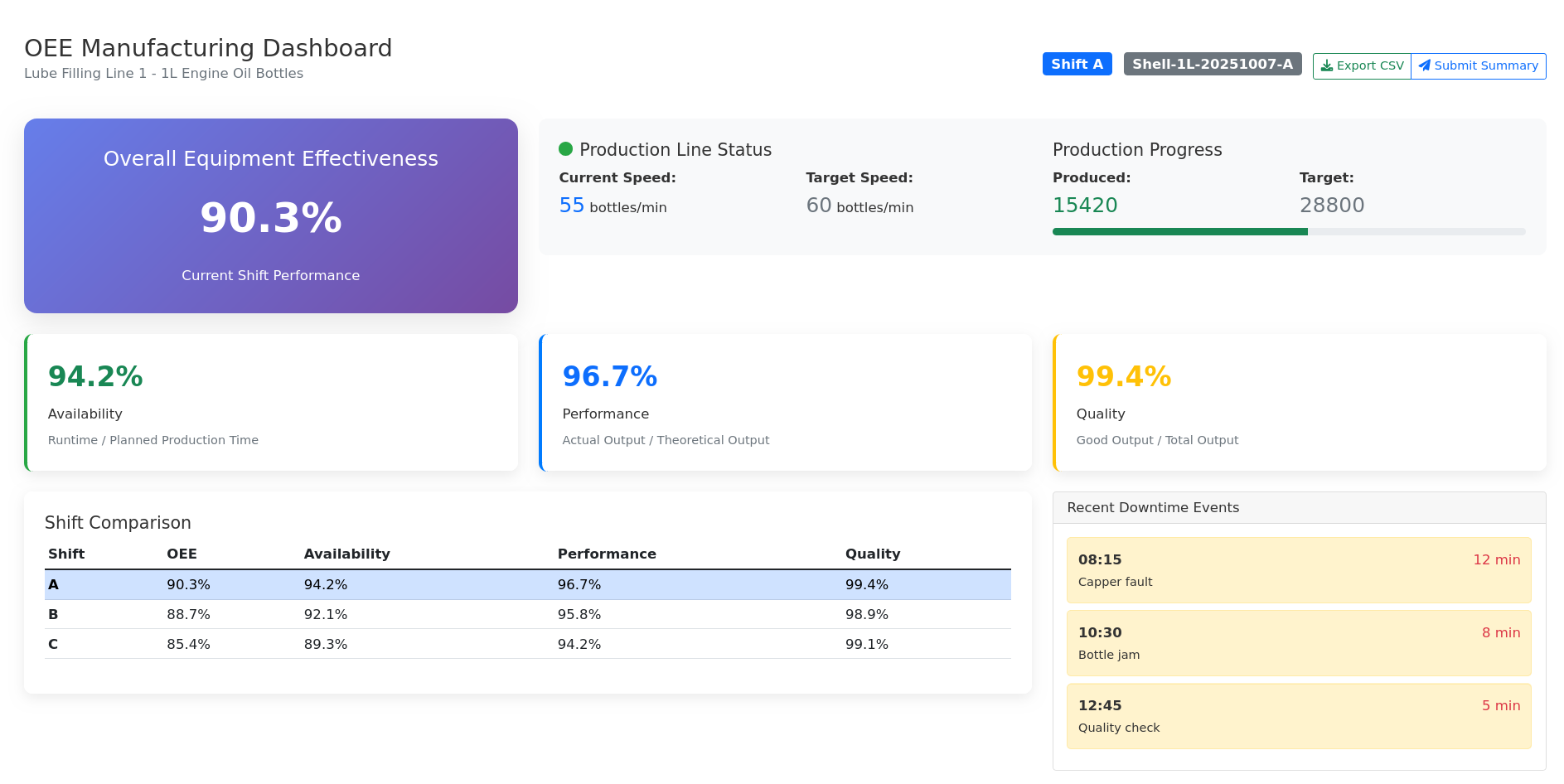

Track what your plant is actually doing — shift by shift, line by line. FMS connects to PLCs, meters, and sensors to give you real-time production visibility with built-in KPI and OEE calculations.

Shift Performance

Automatic shift-based reporting. Know output, downtime, and efficiency per shift without manual data entry.

- Shift start/end auto-detection

- Production count vs. target

- Downtime breakdown by cause

- Shift handover summaries

Downtime Visibility

See exactly when and why machines stop. Classify downtime automatically or with operator input. Trend over weeks and months.

- Automatic stop detection from signals

- Reason code classification

- Pareto analysis of top causes

- Alerts on excessive idle time

OEE-Ready Architecture

Availability, Performance, Quality — calculated from live data. No spreadsheets. Integrated with shift scheduling and production targets.

- Real-time OEE dashboard

- Per-machine and per-line OEE

- Historical OEE trends

- Executive-ready reports

Machine Health

Monitor vibration, temperature, pressure, and runtime hours. Get early warnings before failures happen.

- Analog trend monitoring

- Threshold-based alarms

- Maintenance hour counters

- Predictive alerts via AI layer

Batch & Recipe Tracking

Link production batches to process parameters. Track recipe adherence and flag deviations in real time.

- Batch start/end logging

- Parameter recording per batch

- Deviation alerts

- Traceability for audits

Production Dashboards

Real-time dashboards on any screen — floor displays, control rooms, or executive tablets. HTML5, no plugins.

- Live production counters

- Shift progress bars

- Alarm summary panels

- Multi-site overview